![]()

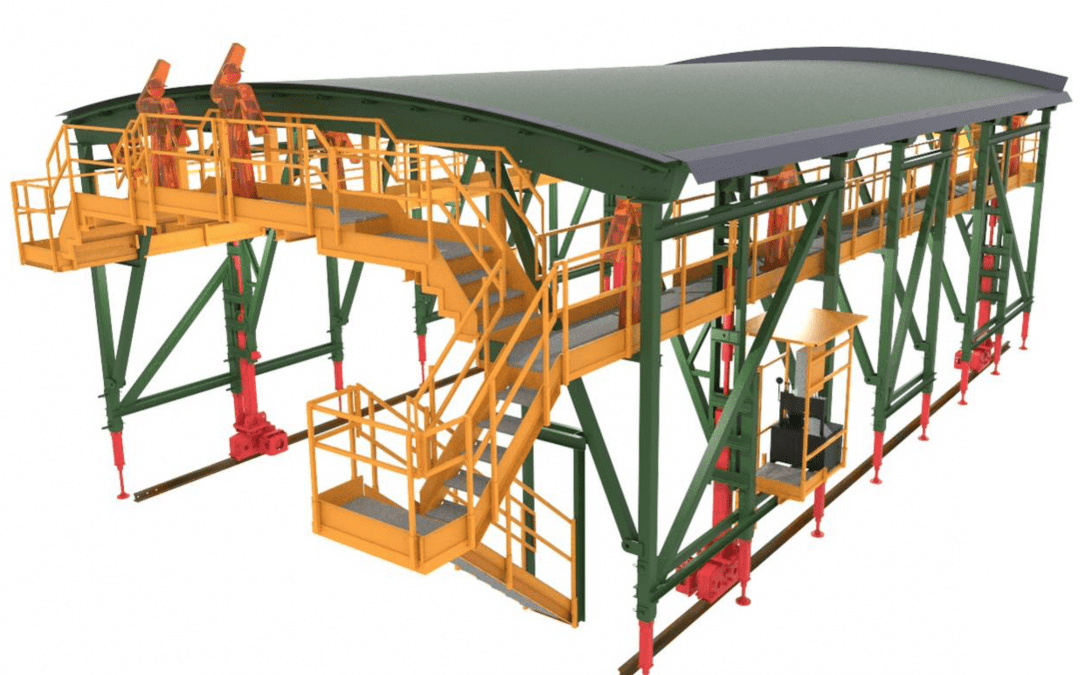

Self-supporting formwork equipment for upper slabs

The equipment allows the concreting of the false ceilings in tunnels where the structural coating has previously been executed.

It is a simple, fast and very effective system that allows a short preliminary preparation and optimal finishes.

The formwork is made up of the panels that shape the slab and the support structure that also allows it to move. By means of a hydraulic system, the lateral “flaps” of the panels are adjusted to the tunnel bracket to achieve a perfect lateral closure. This hydraulic system also allows the ascent, descent and advance of the formwork. The formwork can be moved on railway rails or with rubber wheels directly on the tunnel floor. The rubber wheels give you greater maneuverability and forward speed, while the rails are an inexpensive and simple solution.

It has vibration on the surface of the panels to achieve an excellent finish. Access to work areas is via platforms and ladders that comply with the necessary safety regulations. It also has closure panels at one end and an adaptable overlap piece with the previous setting at the other.

The entire formwork structure is designed to support the weight of the concrete and meet the most demanding requirements regarding the maximum allowable deviations in the section.